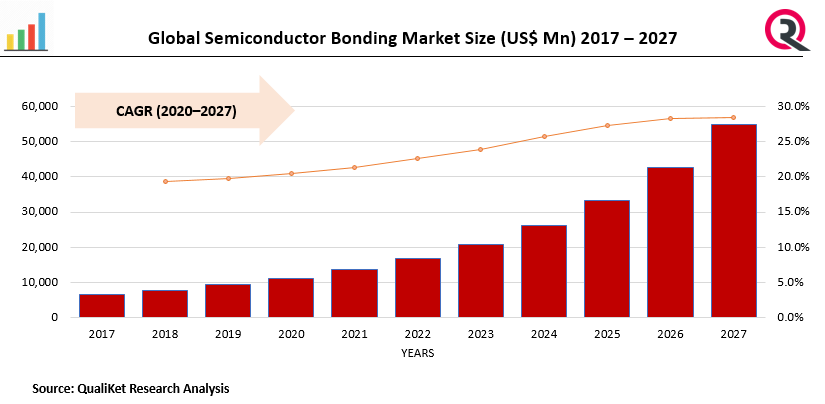

Global Semiconductor Bonding Market Report Size, Trends & Growth Opportunity, By Process Type, By Application, By Technology, By Type, By Region and forecast till 2027.

Report ID : QR1001451 | Industries : Semiconductors and Electronics | Published On :January 2022 | Page Count : 234Global Semiconductor Bonding Market

The global semiconductor bonding market was projected to grow from USD 887 million in 2020 to USD 1,059 million by 2027; it is expected to grow at a CAGR of 3.6% from 2020 to 2027.

Semiconductors’ arrangements comprise of atoms bonded together to form a homogeneous structure and it is used in the making of several integrated circuits (ICs) and fabrication devices. The structure of the material is homogeneous and virtually similar throughout in the bonding model.

Market Drivers

Key driving factor of the Semiconductor Bonding Market is the stacked die technology which is gaining acceptance in a range of electronics applications.

However, the growing demand for microelectromechanical systems (MEMS) is also another driving factor of the market.

Know more about this report: request for sample pages

Market Restraints

High operational cost of ownership is the key factor that restrain the growth of the Semiconductor Bonding Market.

Market Segmentation

Semiconductor Bonding Market is segmented into major 4 categories. Based on Process Type, the market is segmented into Die-To-Die Bonding, Die-To-Wafer Bonding and Wafer-To-Wafer Bonding. Based on Technology, the market is segmented into Die Bonding (Epoxy Die Bonding, Eutectic Die Bonding, Flip-chip Attachment, Hybrid Bonding) and Wafer Bonding (Direct Wafer Bonding, Anodic Wafer Bonding, TCB Wafer Bonding, Hybrid Bonding). Based on Type, the market is segmented into Die Bonder, Wafer Bonder and Flip-chip Bonder. Based on Application, the market is segmented into RF Devices, Mems and Sensors, Cmos Image Sensors, LED and 3D NAND. Based on Region, the market is segmented into North America, Europe, Asia Pacific, Latin America, Middle East.

Regional Analysis

Asia-Pacific is expected to be the dominant regional market because of the faster adoption of advanced technologies in developing countries in the region like China, Japan, India and as technical awareness in the Asia-Pacific is increasing, the market for consumer electronics also rising.

North America is also fast-growing region in the global semiconductor bonding market because of the huge demand for 3D semiconductor assembly and packaging solutions, the growing number of companies is adopting advanced technologies like IoT and artificial intelligence, mainly in the automotive sector.

Market Key Players

Some of the key players operating in Global Semiconductor Bonding Market are Shibaura Mechatronics, SUSS MicroTech SE, Yamaha Motor Robotics Corporation Co., Fuji Corporation, Panasonic, Kulicke & Soffa, ASM Pacific Technology Ltd., Shinkawa Ltd. and BE Semiconductor Industries NV.

Industry development

In October 2020, BE Semiconductor Industries N.V. (Besi) collaborated with Applied Materials, Inc. to develop the industry's first complete and proven equipment solution for die-based hybrid bonding, an emerging chip-to-chip interconnect technology that enables heterogeneous chip and subsystem designs for applications including high-performance computing, AI, and 5G.

In January 2021, ASM PACIFIC TECHNOLOGY (ASMPT) and EV GROUP (EVG) collaborated to create die-to-wafer hybrid bonding solutions for 3D-IC and heterogeneous integration applications. Chiplet technology combines chips with different process nodes into advanced packaging systems that can power new applications such as 5G, high-performance computing (HPC), and artificial intelligence. Die-to-wafer hybrid bonding is a key process for enabling the redesign of system-on-chip (SoC) devices to 3D stacked chips via chiplet technology—combining chips with different process nodes into advanced packaging systems that can power new applications such as 5G, HPC, and artificial intelligence (AI).

In April 2021, ASM PACIFIC TECHNOLOGY (ASMPT) introduced three new manufacturing systems that combine X-Celeprint's Micro-Transfer Printing (MTP) and ASM AMICRA's high precision die bonding technology to introduce the semiconductor industry's first complete system to enable high volume heterogeneous integration of ultra-thin dies onto up to 300mm base wafers.

Global Semiconductor Bonding Market TOC

1 Introduction

1.1 Objective of the Study

1.2 Market definition

1.3 Market Scope

2 Research Methodology

2.1 Data Mining

2.2 Validation

2.3 Primary Interviews

2.4 List of Data Sources

3 Executive Summary

4 Semiconductor Bonding Market Outlook

4.1 Overview

4.2 Market Dynamics

4.2.1 Drivers

4.2.2 Restraints

4.2.3 Opportunities

4.3 Porters Five Force Model

4.4 Value Chain Analysis

5 Network Security Market, By Process Type

5.1 Y-o-Y Growth Comparison, By Process Type

5.2 Semiconductor Bonding Market Share Analysis, By Process Type

5.3 Semiconductor Bonding Market Size and Forecast, By Process Type

5.3.1 Die-To-Die Bonding

5.3.2 Die-To-Wafer Bonding

5.3.3 Wafer-To-Wafer Bonding

6 Network Security Market, By Technology

6.1 Y-o-Y Growth Comparison, By Technology

6.2 Semiconductor Bonding Market Share Analysis, By Technology

6.3 Semiconductor Bonding Market Size and Forecast, By Technology

6.3.1 Die Bonding

6.3.1.1 Epoxy Die Bonding

6.3.1.2 Eutectic Die Bonding

6.3.1.3 Flip-chip Attachment

6.3.1.4 Hybrid Bonding

6.3.2 Wafer Bonding

6.3.2.1 Direct Wafer Bonding

6.3.2.2 Anodic Wafer Bonding

6.3.2.3 TCB Wafer Bonding

6.3.2.4 Hybrid Bonding

7 Network Security Market, By Type

7.1 Y-o-Y Growth Comparison, By Type

7.2 Semiconductor Bonding Market Share Analysis, By Type

7.3 Semiconductor Bonding Market Size and Forecast, By Type

7.3.1 Die Bonder

7.3.2 Wafer Bonder

7.3.3 Flip-chip Bonder

8 Network Security Market, By Application

8.1 Y-o-Y Growth Comparison, By Application

8.2 Semiconductor Bonding Market Share Analysis, By Application

8.3 Semiconductor Bonding Market Size and Forecast, By Application

8.3.1 RF Devices

8.3.2 Mems and Sensors

8.3.3 Cmos Image Sensors

8.3.4 LED

8.3.5 3D NAND

9 Network Security Market, By Region

9.1 Semiconductor Bonding Market Share Analysis, By Region

9.2 Semiconductor Bonding Market Share Analysis, By Region

9.3 Semiconductor Bonding Market Size and Forecast, By Region

10 North America Semiconductor Bonding Market Analysis and Forecast (2021-2027)

10.1 Introduction

10.2 North America Semiconductor Bonding Market Share Analysis, By Process Type

10.3 North America Semiconductor Bonding Market Size and Forecast, By Technology

10.4 North America Semiconductor Bonding Market Size and Forecast, By Type

10.4 North America Semiconductor Bonding Market Size and Forecast, By Application

10.5 North America Semiconductor Bonding Market Size and Forecast, By Country

10.5.1 U.S.

10.5.2 Canada

10.5.3 Mexico

11 Europe Semiconductor Bonding Market Analysis and Forecast (2021-2027)

11.1 Introduction

11.2 Europe Semiconductor Bonding Market Share Analysis, By Process Type

11.3 Europe Semiconductor Bonding Market Size and Forecast, By Technology

11.4 Europe Semiconductor Bonding Market Size and Forecast, By Type

11.4 Europe Semiconductor Bonding Market Size and Forecast, By Application

11.5 Europe Semiconductor Bonding Market Size and Forecast, By Country

11.5.1 Germany

11.5.2 France

11.5.3 UK

11.54. Rest of Europe

12 Asia Pacific Semiconductor Bonding Market Analysis and Forecast (2021-2027)

12.1 Introduction

12.2 Asia Pacific Semiconductor Bonding Market Share Analysis, By Process Type

12.3 Asia Pacific Semiconductor Bonding Market Size and Forecast, By Technology

12.4 Asia Pacific Semiconductor Bonding Market Size and Forecast, By Type

12.4 Asia Pacific Semiconductor Bonding Market Size and Forecast, By Application

12.5 Asia Pacific Semiconductor Bonding Market Size and Forecast, By Country

12.5.1 China

12.5.2 Japan

12.5.3 India

12.5.4. Rest of Asia Pacific

13 Latin America Semiconductor Bonding Market Analysis and Forecast (2021-2027)

13.1 Introduction

13.2 Latin America Semiconductor Bonding Market Share Analysis, By Process Type

13.3 Latin America Semiconductor Bonding Market Size and Forecast, By Technology

13.4 Latin America Semiconductor Bonding Market Size and Forecast, By Type

13.4 Latin America Semiconductor Bonding Market Size and Forecast, By Application

13.5 Latin America Semiconductor Bonding Market Size and Forecast, Country

13.5.1. Brazil

13.5.2. Rest of Latin America

14 Middle East Semiconductor Bonding Market Analysis and Forecast (2021-2027)

14.1 Introduction

14.2 Middle East Semiconductor Bonding Market Share Analysis, By Process Type

14.3 Middle East Semiconductor Bonding Market Size and Forecast, By Technology

14.4 Middle East Semiconductor Bonding Market Size and Forecast, By Type

14.4 Middle East Semiconductor Bonding Market Size and Forecast, By Application

14.5 Middle East Semiconductor Bonding Market Size and Forecast, By Country

14.5.1. Saudi Arabia

14.5.2. UAE

14.5.3. Egypt

14.5.4. Kuwait

14.5.5. South Africa

15 Competitive Analysis

15.1 Competition Dashboard

15.2 Market share Analysis of Top Vendors

15.3 Key Development Strategies

16 Company Profiles

16.1 Shibaura Mechatronics

16.1.1 Overview

16.1.2 Offerings

16.1.3 Key Financials

16.1.4 Business Segment & Geographic Overview

16.1.5 Key Market Developments

16.1.6 Key Strategies

16.2 SUSS MicroTech SE

16.2.1 Overview

16.2.2 Offerings

16.2.3 Key Financials

16.2.4 Business Segment & Geographic Overview

16.2.5 Key Market Developments

16.2.6 Key Strategies

16.3 Yamaha Motor Robotics Corporation Co.

16.3.1 Overview

16.3.2 Offerings

16.3.3 Key Financials

16.3.4 Business Segment & Geographic Overview

16.3.5 Key Market Developments

16.3.6 Key Strategies

16.4 Fuji Corporation

16.4.1 Overview

16.4.2 Offerings

16.4.3 Key Financials

16.4.4 Business Segment & Geographic Overview

16.4.5 Key Market Developments

16.4.6 Key Strategies

16.5 Panasonic

16.5.1 Overview

16.5.2 Offerings

16.5.3 Key Financials

16.5.4 Business Segment & Geographic Overview

16.5.5 Key Market Developments

16.5.6 Key Strategies

16.6 Panasonic

16.6.1 Overview

16.6.2 Offerings

16.6.3 Key Financials

16.6.4 Business Segment & Geographic Overview

16.6.5 Key Market Developments

16.6.6 Key Strategies

16.7 Kulicke & Soffa

16.7.1 Overview

16.7.2 Offerings

16.7.3 Key Financials

16.7.4 Business Segment & Geographic Overview

16.7.5 Key Market Developments

16.7.6 Key Strategies

16.8 ASM Pacific Technology Ltd.

16.8.1 Overview

16.8.2 Offerings

16.8.3 Key Financials

16.8.4 Business Segment & Geographic Overview

16.8.5 Key Market Developments

16.8.6 Key Strategies

16.9 BE Semiconductor Industries NV

16.9.1 Overview

16.9.2 Offerings

16.9.3 Key Financials

16.9.4 Business Segment & Geographic Overview

16.9.5 Key Market Developments

16.9.6 Key Strategies

16.10 Shinkawa Ltd.

16.10.1 Overview

16.10.2 Offerings

16.10.3 Key Financials

16.10.4 Business Segment & Geographic Overview

16.10.5 Key Market Developments

16.10.6 Key Strategie